Four colors Package Bag Flexo Print Machine

Describtion:Suitable Material:1.Paper:

Kraft paper: 40 ~ 350g/m2, single-sided coated paper: 30 ~ 350g/m2, copy paper: 15 ~ 350g/m2, firecrackers and paper: 40 ~ 350g/m2, silicone paper: 50 ~ 350g/m2, coated paper: 30 ~ 350g/m2, dust-free paper: 25 ~ 350g/m2, release paper: 40 ~ 350g/m2composite paper, 30 ~ 350g/ m2

2.Woven:

Woven: 15-120 grams, non woven: 15-500 grams

3.Film:

PVC: 10 ~ 120μ M, OPP: 10 ~ 100μ M, BOPP: 10 ~ 100μ M, PE: 15 ~ 150μ M, NY: 10 ~ 120μ M, PET: 10 ~ 100μ M, CPP: 10 ~ 100μ M

Use:This machine is suitable for printing such packing materials as polyethylene, polypropylene plastic bag, glass paper and roll paper, etc.

And it is a kind of economic printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

Economic Type Flexo Printing Machine Printing Speed: 5-60m/min

High Speed Flexo Printing Machine Printing Speed: 5-80m/min

Feature:Procedure:A. Unwind:

1)Wind Roller: Air Shaft or Mechanical Roller

2)Uewind Control: Friction Type or Tension Control With Magnetic Powder

3)You can choose EPC(Edge Correction System)

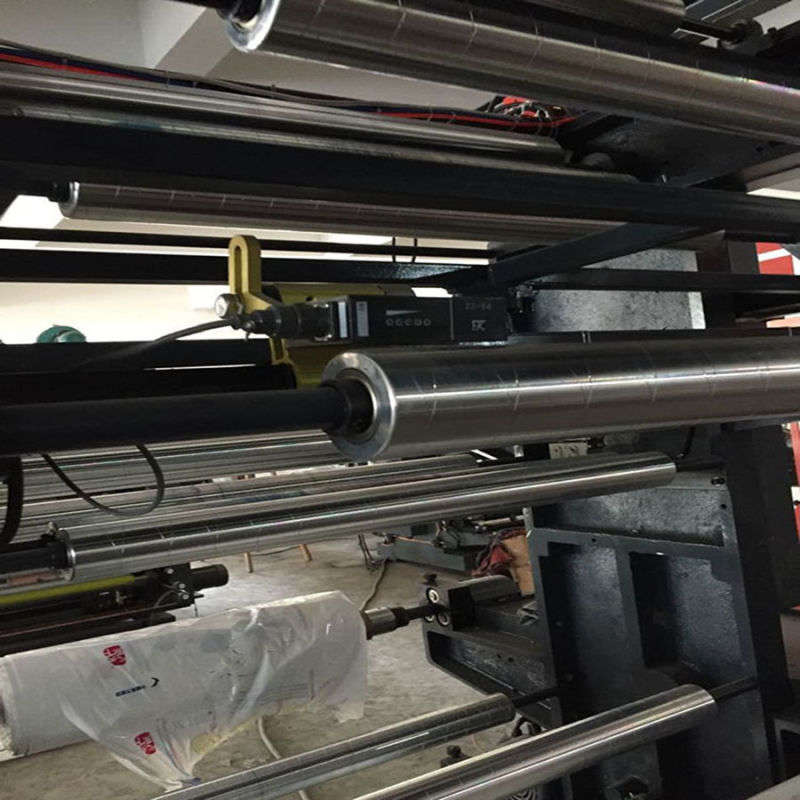

B. Printing Unit:

1)Anilox Roller: Metal Anilox Roller or Ceramic Anilox Roller

2)Doctor Blade: General Doctor Blade(Single Blade) or Enclosed Doctor Blade

3)Ink: Water Ink, Water Base Ink, Alcohol Ink, UV Ink

C. Dryer: Electrical Heating or UV Dryer

D. Rewind:

1)Wind Roller: Air Shaft or Mechanical Roller

2)Rewind Control: Friction Type or Tension Control With Magnetic Powder

Advantage:1. Easy operation, flexible starting, accurate color register.

2. The meter counter can set printing quantity according to the requirements. Stop the machine automatically at the quantity or when the material is cut off.

3. Pneumatic printing cylinder lift and lower, it will stir the printing ink automatically after lifting.

4. The printing ink is spread by the anilox cylinder with even ink color.

5. Reliable drying system coordinated with high-speed rotation, it will automatically break circuit when the machine stops.

6.360° Continuous and adjustable longitudinal register device.

7. The frequency control of motor speed adapts to different printing speeds.

8. There are Jogging/Stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the machine when the plate is installed.

9. Magnetic powder brake for unwinding tension control, magnetic powder clutch for rewinding tension control.

4 Four Color Flexography Printing Machine

Parametes:

| printing machine Model |

YTB-4600 |

YTB-4800 |

YTB-41000 |

YTB-41200 |

Printing Machine color

|

4color(4+0,3+1,2+2) |

4color(4+0,3+1,2+2) |

4color(4+0,3+1,2+2) |

4color(4+0,3+1,2+2) |

| Max. Material Width |

600mm |

800mm |

1000mm |

1200mm |

| Max. Printing Width |

560mm |

760mm |

960mm |

1160mm |

| Printing Length |

200-1100mm |

| Printing Speed |

5-90m/min |

5-90m/min |

5-90m/min |

5-90m/min |

| Max. Diameter of Roll Material |

Φ600 mm(Non woven, filmΦ1000mm) |

| Total Power |

18kw |

20kw |

22kw |

24kw |

| Plate Thickness (including two-sided glue paper) |

2.38mm |

| Machine Weight |

4000kg |

4200kg |

4400kg |

4600kg |

| Overall Dimension |

4.8*1.6*2.4m |

4.8*1.8*2.4m |

4.8*2.0*2.4m |

4.8*2.2*2.4m |

| Working Voltage |

380V 3-phase 50Hz |

Main Devices:

1) EPC web guider + Auto tension controller

2) Air Shaft

3)Ceramic Anilox Roller + General Doctor Blade

4)Motor(Taiwan) + Electric Parts (Siemens)Extra Optional Devices:

1) Enclosed Doctor Blade

2) PLC Control

3) Computer Graphics Detection System |

|

| Payment |

TT, LC at sight |

| Mini order |

1Set |

Delivery time

|

30 days after receive the deposit |

Packing and Marking

|

By standard export packing. If have Mark, please tell us before shipment. |

Installation

|

If need our engineer go to your country to install, please repare the material and bulid machine firstly. Also buyer should take charge the tickets go and back, live, food and salary of our engineer. |

Guarantee

|

One year, machine trouble is caused by nature not by human force from delivery time . Easily wear parts also is one year. after sale service for all life. |

We are a professinal machine manufacturing factory,specialized in production of flexo printing machine,slitting machine and cutting machine.we have been in this line over 10 years.we can give you 100% guarantee for machine quality.choose us will give you unexpected gain!!!

Don't hesitate to contact wtih me,we will provide themost suitable machine with high quality and factory price!

Don't hesitate to contact wtih me,we will provide themost suitable machine with high quality and factory price!  Company Profile

Company Profile